Metal Fabrication

E.E. URD Design and Manufacturing offers precision OEM metal fabrication services, specializing in, investment casting/lost wax, sand/gravity casting, die casting, precision machining, forging/cold heading, metal injection molding (MIM), sintered/powder metal, fine blanking and metal stamping/fabrication/forming for manufacturing parts, components and assemblies. E.E. URD Design and Manufacturing offers precision OEM metal fabrication services, specializing in, investment casting/lost wax, sand/gravity casting, die casting, precision machining, forging/cold heading, metal injection molding (MIM), sintered/powder metal, fine blanking and metal stamping/fabrication/forming for manufacturing parts, components and assemblies.

Capabilities:

- Engineering and manufacturing services: R&D processes, tooling and gauging, jig and fixture design, and prototype development.

- Design, integrated 3D CAD/CAM system,

- Total quality management (TQM) programs and statistical process control (SPC) product quality.

- Inspection equipment & Procedures: Vacuum emission spectrometer, CE meter, X-ray, ultrasonic, metallurgical microscope, micrographic analysis, universal/hardness/molding tester, immersion thermometer, wedge inspection, shear and tensile testing, liquid penetrant inspection, radiographic, gauge, CMM (coordinate measuring) and 3-D layout machine inspections, 3-D CAD/CAM, deform simulation of forging process.

- Materials: Aluminum / Al alloy, Zinc / ZN alloy, Nickle, Titanium, Magnesium, carbon steel, tool steels, steel alloys, Stainless Steel, Fe-Ni, Tungsten, ND, FeB magnetic, NiTi, Brass, Copper, Bronze, gray cast iron, ductile iron, cast steel.

- Standards and Approvals: ISO 9001, QS 9001, TS 16949, ASTM, AMS, AS 9100, MIL-STD, MIL-I-45208 and MIL-STD-45662A, as required.

- Surface treatment types: plating / ZN & chrome plating, coating, phosphate, anodizing, CVD/PVD plating and coating, blackening, and fine polishing.

- Heat Treatment as required: annealing, normalizing, tempering, nitriding, carbonitriding, carburizing, induction hardening.

Applications:

- Aerospace and military industries.

- Computer industries

- Automotive industries

- Electrical and electronic industries

- Medical, hydraulic and pneumatic industries

- High-end hardware product industries.

Precision Machining:

CNC Milling and turning, grinding, horning, lapping, broaching

Forging and Forming

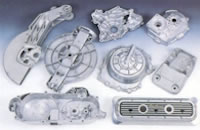

Die Casting:

Sand and Gravity Casting:

|

|

Investment Casting

Cold Forged / Cold Heading Parts:

Fasteners, bolts, nuts, blind nuts, metal bushings, tubing with blind hole, special screws and bolts, shafts and ball joints.

Metal Injection Molding:

Advantages include: cost saving as compared to machining, more complex shapes, high precision within +/- 0.3%

Stamping and Forming:

Stamping, fine blanking, fabrication and assembly.

|

|